Weight savings

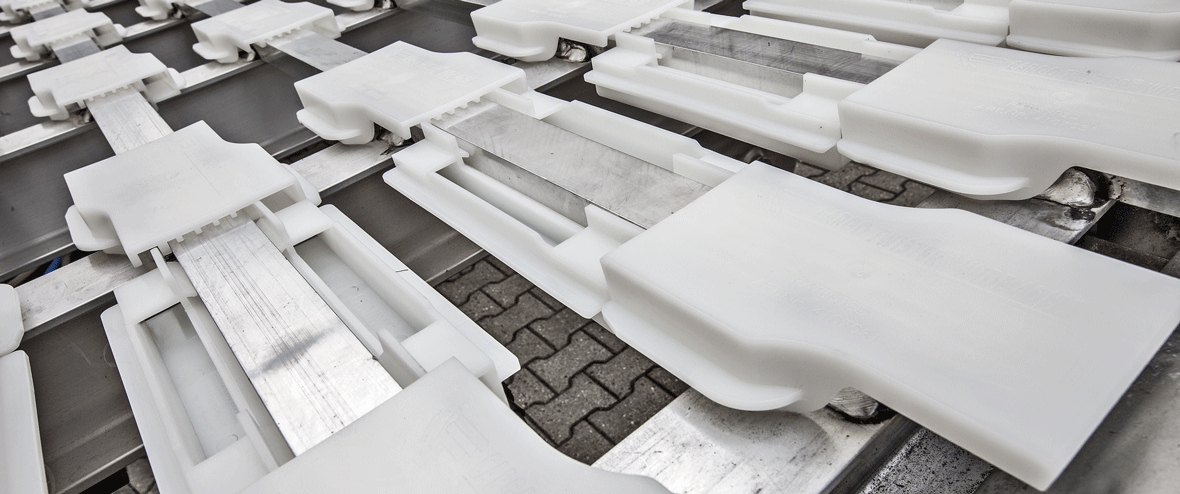

Cargo Floor has developed an alternative moving floor to ensure that the system is even lighter in a responsible manner. This concerns a sliding floor that has 15 moving floor profiles instead of the usual 21; the total moving floor area has remained the same.

Primarily bulk products

This moving floor system is unsuitable for the loading and unloading of pallets and paper rolls when using the sliding operation of the Cargo Floor system because the floor profiles linked to the Cargo Bulkmover concept are wider than the standard 21 plank model. Pallets, etc. can, obviously, be loaded and unloaded appropriately by moving a hand pallet or forklift truck over the floor. More than 20 years of experience with wide floor profiles in mainly stationary factory applications has shown that the 15 plank Bulkmover variant of the Cargo Floor system is extremely suitable for the efficient unloading of most bulk products in large volumes.

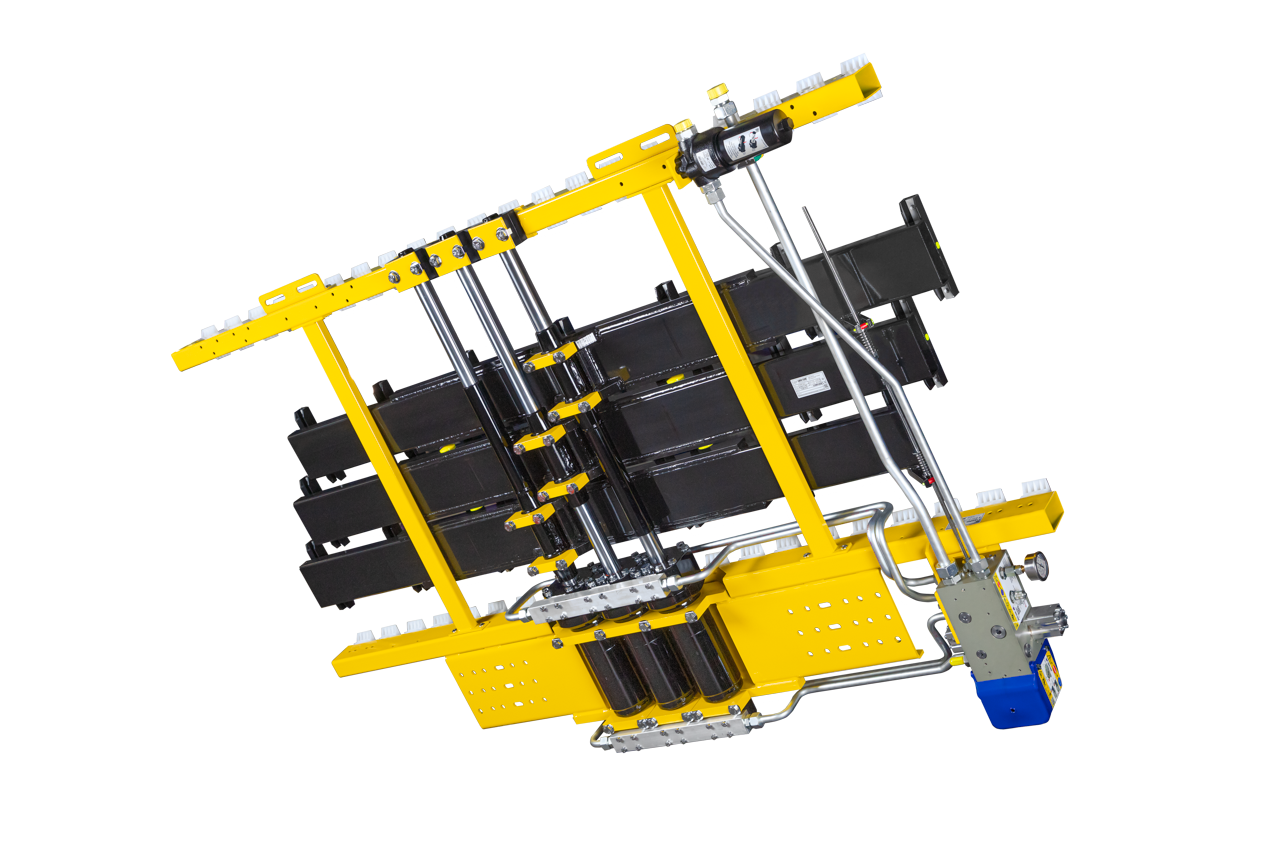

A special bearing has been developed to ensure sufficient stability and load bearing based on the patented Cargo Twister principle. This continues to guarantee fast and simple installation without having to use tools. The additional advantage of the Cargo Bulkmover is the fact that no fewer than 30% less bearings need to be installed. This

A special bearing has been developed to ensure sufficient stability and load bearing based on the patented Cargo Twister principle. This continues to guarantee fast and simple installation without having to use tools. The additional advantage of the Cargo Bulkmover is the fact that no fewer than 30% less bearings need to be installed. This