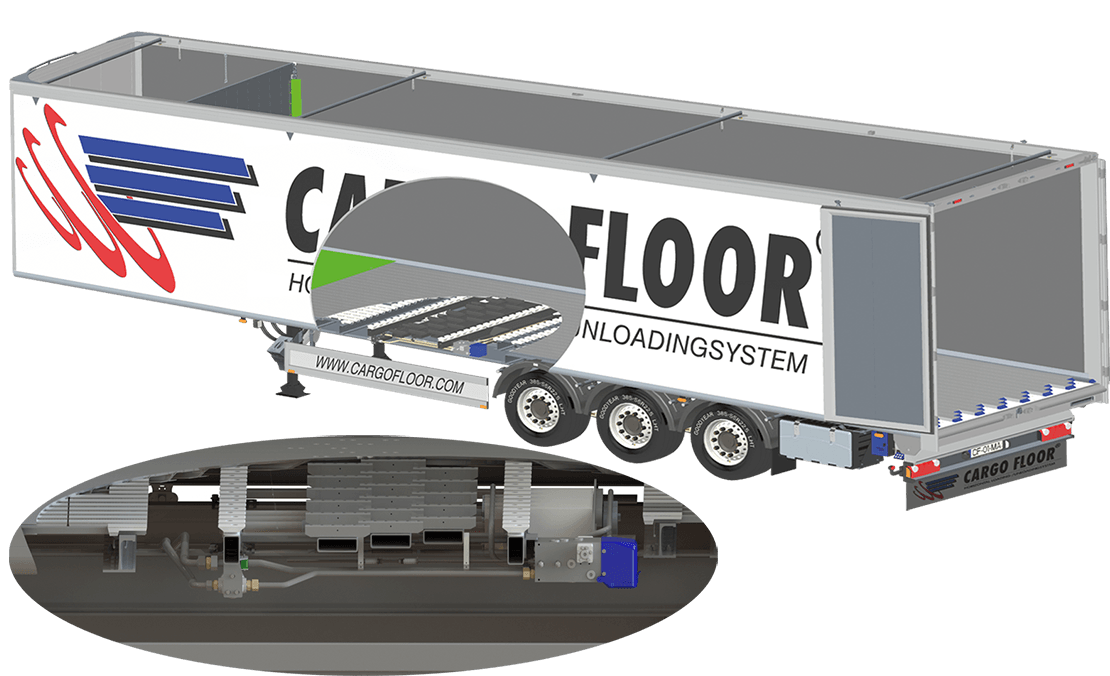

The Cargo Floor moving floor 'sliding floor' system is a multifunctional operating unloading and loading system with which you can transport (unload and/or load) very different products fast and efficiently horizontally (without having to tip).

Firstly, this transport system is extremely suitable for unloading very different bulk products that are normally loaded from the top and are safely unloaded horizontally through the rear side by the Cargo Floor 'sliding floor'. Secondly, you can also load and unload packaged products such as pallets, paper rolls, etc.

Safe, efficient, cost-effective & reliable

Cargo Floor systems are not only designed to move products faster, safer and smarter, but in particular also cheaper than conventional options. Important features are:

- extremely safe

- working horizontally

- durability

- environmentally friendly

- no physical exertion

- maximum volume

- light in weight

- low operating costs (low maintenance)

- efficient

- profitable

- reliable

- both quick loading and unloading

- short payback period